The South African

The South African

Sir Charles comes of age

When one examines the background of rifles used successfully in battle by the forces of the British Empire during its days as a world power, several points become apparent: Their design was influenced by input from a number of sources, they were manufactured by large concerns at various centres and they evolved over a period of time. Yet there was another rifle, also used by the British, which was created by one man, produced in his own factory and which went into battle soon after a major design change. If the former system was a recipe for success, what was the outcome of the latter? The following account of this unusual arrangement commences on 4 April 1872. On that day was born into one of the most aristocratic families in Scotland, a boy who was christened Charles Henry Frederick Augustus Lockhart Ross. When he was eight, he succeeded his father as the Ninth Earl of Balnagowan. He was heir to estates of some 350 000 acres encompassing some of the best hunting and agricultural land in the United Kingdom. On these estates there were no less than 3 000 tenants and he was one of the richest men in the British Isles. To match his material possessions, he was intellectually brilliant, passed through Eton and graduated from Cambridge with a degree in engineering.

Straight-pull bolt action

With some of the best shooting land in Scotland at his disposal it is not surprising that Sir Charles developed an interest in rifies at an early age and, with his mechanical bent, soon turned to designing them. Very significantly, Sir Charles appears to have fallen in love with what is technically known as the straight-pull action, which was then most commonly found in the Austrian Mannlicher and the Swiss Schmidt-Rubin rifles. In pursuit of this obsession, he took out his first patent covering the design of an unrealistically complicated action while still an undergraduate at Cambridge (Phillips & Knap, 1967, p 265).

It is appropriate here to consider the difference between the breech mechanism of the straight-pull bolt action rifle and that of the standard design such as the contemporary British Lee Enfield. A normal bolt action rifle is reloaded by raising the bolt handle to unlock the breech. The bolt is then retracted to withdraw the spent cartridge case from the chamber and eject it. A forward thrust of the bolt strips a fresh cartridge from the magazine and propels it into the chamber. Finally, the bolt handle is depressed to lock the action before firing. There are thus four movements which are relatively time-consuming. These rotary movements are supplied by the shooter's wrist and the action is locked by two or more solid lugs on the bolt which slot into recesses machined in to the action. In Sir Charles' straight-pull design, the rotary action was imparted to a rotating bolt-head with two solid locking lugs by spiral grooves inside the bolt itself. These acted against corresponding internal cams, unlocking the breech when the bolt was pulled back to eject the spent case and locking it when the bolt was pushed forward to chamber a fresh cartridge. There were thus only two movements against the four of the standard rifle - a potentially much faster action (Handbook for the Canadian Service Rifle, 1913, pp 20-22).

However, there is one very serious drawback in the straight-pull design as compared to the standard bolt-action. In the standard pattern there is invariably a slight angle to the leading edge of one or more of the locking lugs. When the bolt handle is raised, a considerable camming force thus acts on the spent cartridge, helping to force it out of the chamber. This is of particular significance if the cartridge case is, for any reason, inclined to stick. In the straight-pull action, without the leverage provided by a projecting bolt handle, this primary extraction force is minimal.

Opportunities in Canada

In 1897, at the age of 25, Sir Charles moved his centre of operations to Canada where, as a shrewd Scot, he correctly believed lay significant business opportunities. Here he soon increased his already considerable fortune by such activities as the design and installation of a hydro-electric plant and arranging a transport system. He also took out patents in the hydraulics field and covering improvements to the design of ships' propellers. As a significant social success, he made many useful contacts amongst the Canadian political elite. He also found time, however, to redesign his straight-pull action, basing it even more closely upon the Mannlicher. Sporting rifles of this pattern were manufactured in both the United States and England.

During this period, the Anglo-Boer War broke out in South Africa and, with its expanding military forces, the Canadian Government faced a serious arms shortage. Previously Canada, like the rest of the British Empire, had relied upon the mother country for its supply of rifles, but under wartime pressures this source of supply dried up. Following a fruitless quest in England, the Canadians decided that they would have to become self-sufficient. The time was ripe and, using his political connections, Sir Charles made an offer that the Canadian Government found most attractive. As a result he invested $500 000 of his own money to build a rifle factory in Quebec. Naturally the rifle was to be of his straight-pull design, but in a military configuration and chambered for the British .303 service cartridge. Whether the actual testing of his sample rifles actually warranted this step is doubtful since they showed a tendency to operate stiffly when hot and would occasionally jam. However, under the circumstances, the Canadian Government had little choice and in March 1902, it signed a contract with Sir Charles for him to deliver 12 000 rifles during 1903. (Phillips & Knap, 1969, p 11).

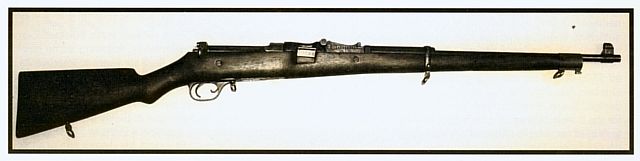

The Ross Rifle Mk I

The first 1 000 of these rifles, the Ross Mk I, were delivered almost two years late in 1905 and issued to the Canadian Mounted Police. Problems immediately became apparent. Parts had been manufactured in the United States and were defective. Springs were poorly tempered, bolts fell out, and comparative tests against the Lee Enfield proved the Ross to be markedly inferior. To aggravate this situation a militiaman was killed when his rifle exploded and a police sergeant-major was seriously injured when part of a bolt blew back in his face. Questions were raised in the Canadian and British parliaments, but Canada was already committed to Sir Charles and his rifle. The Mk Is were merely recalled and later returned to the factory.

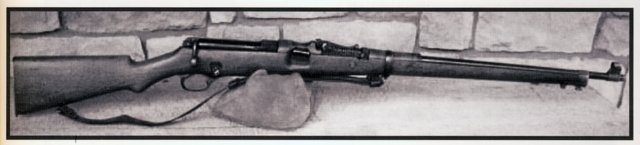

The modified Ross Rifle Mk 11**

The Mk II version of the military Ross Rifle was issued in late 1905 and, eventually, following some seventy modifications over the next six years to improve its military capabilities, emerged as the Ross Mk 11**. This rifle was probably as effective as any weapon using the straight-pull design could be. It was also incredibly accurate, taking almost all the prizes at Bisley over the period 1909 to 1913, including the King's Prize in 1913. In that year, also, it was used to defeat the Americans at their own Camp Perry, where the Canadian team walked away with the Palma Trophy. (Phillips & Knap, 1967, pp 268-9).

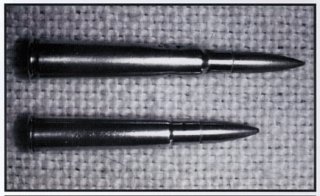

A new cartridge

With the success of the Mk 11** Rifle, the previous criticisms of the military Ross were largely stilled, at least for the time being. It is probable that, had Sir Charles persevered with this rifle, this story would have had a very different ending. However, the restless and ambitious Scotsman was not content to rest on his laurels and in 1908 he developed a superb cartridge in .280 calibre. At this date, with a muzzle-velocity exceeding 3 000 feet (914 metres) per second and a pointblank range of about 500 yards (457 metres), it was probably about 70 years ahead of its time. In 1910 followed a sporting rifle with a specially redesigned action to handle this magnificent cartridge. The combination proved both successful and popular, with the rifle being named the Model 1910 or M-10 and the cartridge known as the .280 Ross.

In comparison with the .280, the muzzle velocity of the contemporary .303 British military Mk VII cartridge was a mere 2 440 feet (743 metres) per second. From a military point-of-view this was most significant since a flat trajectory considerably enhances accuracy in the course of a fast moving battle where soldiers under stress often fail to adjust their sights. Sir Charles consequently hatched a scheme to persuade, firstly, the Canadian Government and then, hopefully, the United Kingdom and the rest of the British Empire, to adopt both the Ross Rifle and his new cartridge as the standard military package. What he had already achieved would be nothing compared to what could lie ahead!

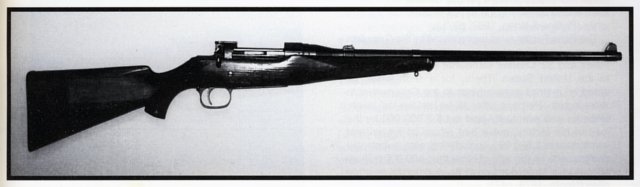

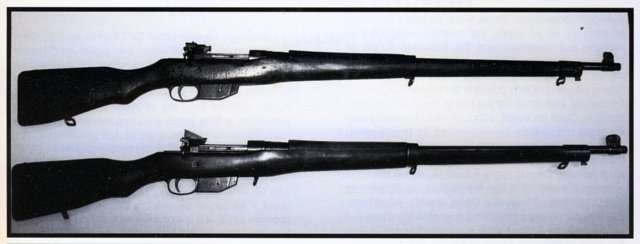

The Military Ross Rifle Mk III

There was, however, in Sir Charles' active mind, a slight problem. Perhaps the action of the successful Mk 11**, while sufficiently strong for the standard .303 cartridge, was not ideally suited to the powerful .280. He consequently designed a new service rifle, the Ross Mk III in the standard .303 calibre, but using the same action that had been developed for the Model 1910 Sporter. Cannily, the scheming Scotsman incorporated a barrel which could be quickly exchanged for one chambered to accept his .280 cartridge, and a magazine which was also easily modified.

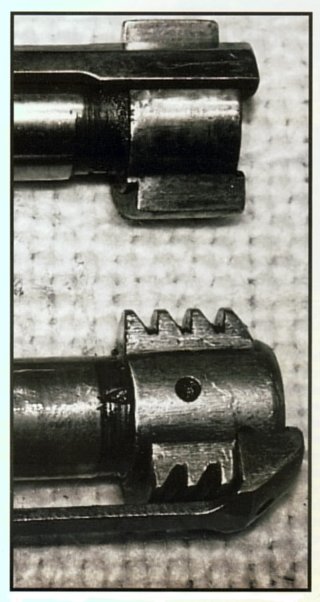

In many respects, the action of this rifle was similar to the Mk II series, but there were two very important differences: Firstly, instead of having solid locking lugs on its rotating bolt-head, these lugs were in the form of an interrupted thread somewhat similar to those found on artillery breeches. Thus when the bolt-head was rotated upon the forward stroke of the bolt, the teeth of the locking lugs engaged corresponding slots in the action which locked it behind the cartridge. This arrangement was incredibly strong and has withstood pressures approaching 150 000 pounds per square inch. The contemporary British Lee Enfield would have failed at less than half of this.

The second major change involved a rotary bolt-stop mounted at the side of the action which had three positions. Two of these, respectively, permitted the use of the magazine or confined the rifle to loading one cartridge at a time, thus keeping the magazine in reserve. The third position enabled the bolt to be withdrawn from the rifle (Handbook for the Canadian Service Rifle, 1913, pp 7-8). Most significantly, in the first two positions, the rearward movement of the bolt was checked by the rear tooth of the left locking lug hitting against the bolt-stop.

Following limited trials, the Military Ross Mk III was rushed into production towards the end of 1912 with full output being achieved in early 1914. Like its predecessor, the Mk 11**, this rifle was pleasingly accurate, but weighed almost ten pounds (4,5kg) and, with bayonet fixed, was over five feet (1,52 metres) in length.

Detested in the field

Then came August 1914 and, with it, the First World War. It was the British now who were short of rifles and, in September, the War Office placed an order for 100 000 Mk III rifles of a slightly modified pattern, the Mk III B (or British), to be delivered the following year. With the British Government as a customer, Sir Charles, it would seem, had made significant progress towards achieving his goal.

The First Division of the Canadian Expeditionary Force arrived in France to fight alongside the British in February 1915. They were armed with the Canadian version of the Mk III and were soon locked in battle. From the very start, their musketry experiences were disastrous. The Ross quickly earned an evil reputation for jamming solid in the heat of battle, thus making it extremely difficult to reload after firing. Canadian soldiers faced the advancing grey hordes shedding tears of rage and frustration. Desperate measures were taken. Bolts were beaten open with entrenching tools and stamped upon with mud-encrusted boots. When it was indeed possible to fire the Ross, the bayonet often fell off. As compared to the Lee Enfield, the firing efficiency of Ross-equipped soldiers was estimated to be about 20%. The long, heavy rifle was also difficult to manipulate in the often confined spaces of trench warfare.

The Canadian soldiers soon learned to detest the Ross and, wherever possible, exchanged their rifles for those taken from British casualties. This arrangement was soon formalised and, before long, the whole of the First Division was equipped with Lee Enfields. Sir Charles, however, had powerful political connections and the next three Canadian divisions also carried the Mk III Ross. They experienced exactly the same difficulties! Obviously, every effort was made to establish the cause of the jamming problem. Theories ranged from poor care and cleaning to defective British ammunition, trench mud in the locking grooves and over-tight chambers. There were certainly elements of truth in all of these, but maintenance training, reaming out chambers and the exclusive supply of Canadian-made ammunition did little to improve the situation. To add to the problem, it was also found that, during cleaning, it was possible to reassemble the bolt incorrectly, thus enabling the rifle to fire in an unlocked position. Such an event, although rare, invariably had the most unfortunate consequences for the rifleman, who at the very least would be seriously injured with the bolt tearing off half his face. The name 'Ross' soon became anathema to those forced to use his rifles.

It was not until 1916 that the main cause of jamming was identified. Obviously, under muddy conditions, the lack of primary extraction inherent in the design of all straight-pull actions was a contributing factor, but the main culprit was found to be the bolt-stop acting against the left rear locking tooth. Here the area of contact was only about one hundredth of a square inch and when the bolt was violently retracted during rapid fire, or being hammered open when stuck, the bolt-stop soon deformed and damaged the locking tooth, causing it to jam. The more the bolt stuck, the harder its retraction - a vicious circle (Phillips & Knap, 1967, p 269).

This problem was eventually remedied by doubling the area of contact on the bolt-stop. Similarly, the possibility of the bolt being incorrectly assembled was cured by the insertion of an internal rivet. Nothing, however, could be done to resolve the weapon's other faults and, in any case, the Canadian soldiers had lost all confidence in Sir Charles and his rifle. Not surprisingly, the British also cancelled their overdue order after some 67 000 Mk III Bs had been delivered. The final blow came in May 1916, when Sir Douglas Haig ordered that all Ross rifles be recalled and the Canadians rearmed with Lee Enfields. This exchange was completed by mid-September.

A few Mk IIIs equipped with telescopic sights were retained by the Canadian snipers, who appreciated their superb accuracy and were generally better qualified to nurse their rifles than the ordinary soldier. Many of those withdrawn were re-issued to the Royal Navy, seeing further service in both World Wars. Others were used in training, thus releasing Lee Enfields for the front. A large number went into storage and were eventually issued to the Home Guard in the Second World War. Others were sent to Russia, while some even ended up arming the forces of Luxembourg for a while (Phillips & Knap, 1967, p271).

The Ross Factory was expropriated by the Canadian Government with a plan to manufacture Pattern 1914 Rifles and Sir Charles somewhat hurriedly relocated to the United States. There, for a short while, he acted as a small arms advisor to the Government in Washington. Perhaps, after all, he had the last laugh, since he was eventually paid out $ 2 000 000 for the loss of his factory, not a bad return on his original investment of $ 500 000, considering, also, substantial profits made on the sale of more than 400 000 military rifles and a large number of his successful sporting rifles (Nonte, 1973, p47).

Conclusion

What can be said about Sir Charles as a person? There is no doubt that the man was a genius with many inventions to his credit. Unfortunately, his main efforts were directed into an evolutionary dead-end. The rifle he developed belonged to a class which, however well made, suffered from the inherent weakness of poor extraction, a fault which was exacerbated by dust or mud. These conditions were all too prevalent during the First World War and, in the case of the Ross Mk III, were combined with design faults which should have been rectified before it was used in battle. The problem was Sir Charles' ambition, impatience and neglect of detail. If he had stuck with the successful Mk II**, the chances are that it would have withstood the rigours of trench warfare far better than did its successor, the Mk III. But, alas, it was rushed into production before serious problems had been ironed out, in the hope that it would initiate a small arms revolution in the British Empire. Sir Charles was over-hasty and the expropriation of his factory marked the demise of his excellent sporting rifles, a wonderful cartridge and what could have become the nucleus of an industrial empire.

Perhaps the circumstances of his downfall are best summarized in the words of a contemporary armaments publication, Arms and Explosives, quoted by Phillips and Knap: 'The commercial knowledge necessary to such a concern was there, but the inventor's love for the product of his ingenious brain brought about disaster, when by all the hard rules of commercialism he should have produced something which the world wanted, and not something which he wanted the world to have' (Phillips & Knap, 1969, p 22).

Bibliography

Handbook for the Canadian Service Rifle (Government Printing Bureau, Ottawa, Canada, 1913).

Phillips, R & Knap, J 'Sir Charles Ross, Bart. and his ill-fated rifles' in The Gun Digest" 21st Edition, 1967, Follett Publishing

Phillips, R & Knap, J Sir Charles Ross and his Rifle (Historical Arms Series No 11, Museum Restoration Service, Ottawa, Canada, 1969).

Nonte, G 'Sir Charles Ross and his Rifles' in The Rifle Magazine, March-April 1971, Dave Wolf Publishing Company, Prescott Arizona. USA

Return to Journal Index OR Society's Home page

South African Military History Society / scribe@samilitaryhistory.org