The South African

The South African

Part One of this article, 'Organisation and Services', was published in Military History Journal, Vol 14 No 4, December 2008. As in the first part, use of the term 'the Battery' in the following article refers to No 10 Mountain Battery, Royal Artillery. Author's note: Some of the particulars of the 2,5-in Steel (Jointed) RML contained in the paragraph below are included in Maj D D Hall's article, 'Guns in South Africa, 1899-1902', in Military History Journal, Vol 2 No 1, June 1971, but are repeated here for completeness.

The Battery's Ordnance

The 2,5-in RML had first seen service in Afghanistan in 1879 and, although still useful enough against irregulars who did not have artillery, it was obsolete by 1890. Nonetheless, its replacement, the 10 pr Breech-Loading Mountain Gun, was only adopted for service in 1901. The particulars of the 2,5-in RML are as follows:

• Barrel overall length: 70,45 in (1,789 m)

mass of breech: 201 1b (Mk I); 200 lb 8 oz (Mk II)

mass of chase: 199 1b(Mk I); 2041b (Mk II)

calibre: 2,5 inches (63,S mm)

• rifling grooves: 8

• Maximum range (with common and ring shells)

4 000 yards (3 656 m)

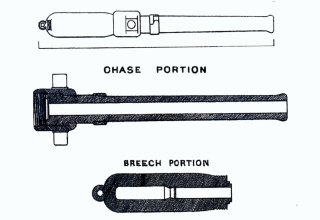

The 2,5-in RML Steel (Jointed) Gun, Mk I.

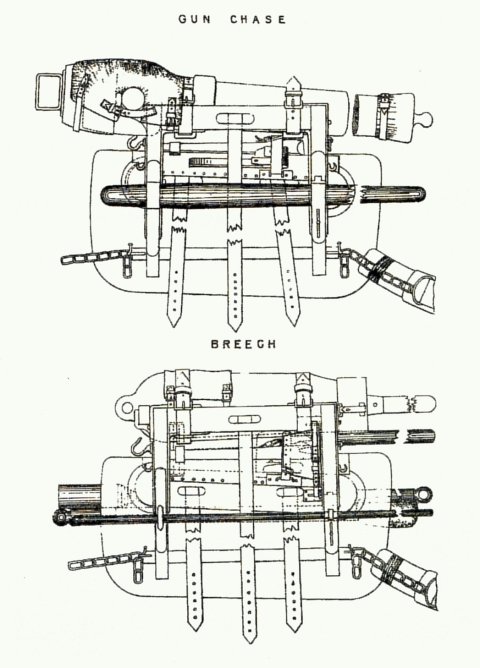

The jointed steel barrel, which had originally been proposed by Col le Mesurier, RA, was developed at Sir G W Armstrong and Mitchell's Elswick Ordnance Works in Newcastle. It consisted of a separate breech portion and a chase with the junction nut. The junction nut, which was fixed to the chase whilst revolving free on it, also served as a trunnion ring and was used to screw the chase onto the threads cut in the open end of the breech portion. The chase included a feather, which fitted into a slot on the breech portion to ensure that the rifling of both portions would be properly aligned. Arrows with the wording, 'TIGHTEN' and 'SLACKEN', were stamped in appropriate positions on the shoulders of the trunnions, both above and below them in the case of the Mk II gun. The junction nut was also engraved with the crown, garter and the Queen's 'VR' cipher. The junction nut had to be tightened and slackened by striking the left trunnion with a dismounting hammer, but only after a thick, circular steel trunnion block had been placed on it. For this operation, the whole barrel was up-ended, breech first, in a cylindrical dismounting block fitted on top of the carriage trail shoe, where it was held in position by an iron shifting bar which was passed through a hole in the cascable button and fitted into slots in the block.

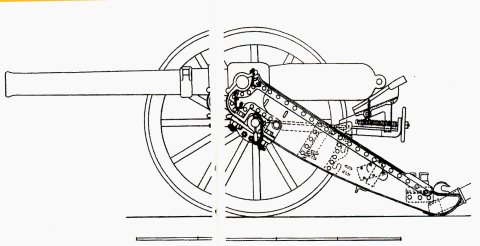

Elevation of the 2,5-in RML Steel (Jointed) Gun Mk I and Carriage Mk II. Scale: 4 ft.

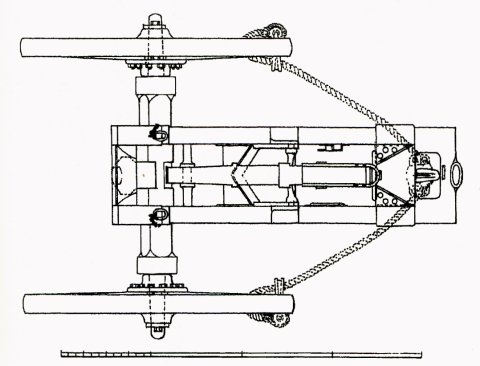

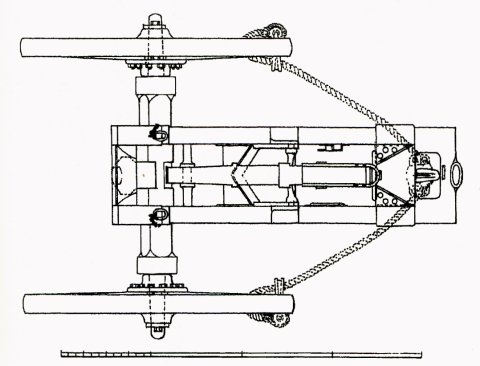

Plan of the Carriage, Mk II, with Mk II axle. Scale: 4 ft.

The gun had a plane for a clinometer machined on top of the breech just in front of the vent and could only be sighted on either side, a fore sight with a circular aperture being held in either of two brackets on a ring on the chase just in front of the junction nut, and a rear tangent sight in the corresponding socket at the breech, one socket being drilled on each side of the breech. A special tangent sight with a reciprocating bracket was issued for use in cases when ground prevented the axis of the trunnions from being horizontal.

The carriage was made of two steel brackets flanged along the top and bottom edges and with a length of angle-iron rivetted under the upper flange to strengthen it. The brackets were joined eight inches apart by a steel plate at the breast, a steel transom and a steel trail shoe which included a socket for the handspike. There were two marks of the carriage in service by 1896 and a third and fourth by 1899, the difference being only in small details such as brackets for the wad hook worm and dismounting hammer, although masses differed between the various marks by up to almost 8 lb. The elevating gear consisted of a 'T' section iron slide, or stool bed, to which was fixed a wood shod gun metal quoin capable of being moved back and forth under the breech by a screw with a gun metal hand wheel.

The slide was pivoted at the front on a cross bar between the carriage brackets and rested at the other end in two racks, the latter providing four alternate positions for large adjustments of elevation. The whole elevating arrangement could be easily lifted out of the carriage. The solid steel axle, held in housings in the carriage brackets by clip plates and bolts, was also removable. Axle arms for mountain guns had neither 'lead' nor 'hollow' and held the wheels parallel to each other in a vertical plane. The iron shod wooden 'No 67 Mk II' wheels had iron ring tyres and a diameter of only three feet. Wheel weights differed slightly depending on whether the naves were made of iron or the heavier gun metal.

The carriage did not have any means to control recoil other than a rope, which was hooked around a felloe of one wheel, passed around a hook on the carriage trail shoe, and then hooked around a felloe of the other wheel. When not in use the rope was hooked to rings on the trunnion cap squares.

Sketch of the gun and carriage, omitting the right wheel.

The writer is not aware of any record of the marks of gun and carriage issued to the Battery, but in 1974, at the Drill Hall in Harare, he was able to examine one of the Battery's guns that had been acquired by the British South Africa Company in 1896 (for an historical account, see Part One of this article in MHJ Vol 14 No 4). That gun was a Mk I and the carriage, which was without its elevating gear, appeared to be a Mk II version with a Mk II axle. This axle differed from the Mk I pattern originally used with this type of carriage, in that the shoulders were built up to provide wider bearing surfaces for the wheel nave.

AMMUNITION

Cartridges Gunpowder, or black powder as it was called in the services, was the only explosive used to make up cartridges for the 2,5-in RML. In 1899, it was essentially still the same mixture of 75 parts saltpetre, 15 parts charcoal, and ten parts sulphur as it had been in the Napoleonic Wars but its form had changed over the years. As compared with smooth bores, rifled muzzle-loading artillery required a slower acting powder to more gradually overcome the resistance of its close-fitting projectiles and avoid damaging the bore. This had resulted in the development of rifle large grain, or RLG, powder, which burned more slowly than the fine grain variety previously in use. RLG powder was made in several grades of which one was especially produced for India and other hot climates.

Cartridges were made up in measured quantities of powder contained in 'silk' cloth bags that were bound with loops of worsted twine to keep them in shape. In 1901, the 2,5-in RML was using service charges of 1 lb 8 oz or 1 lb 11 oz, the mass depending on the grade of powder.

Whatever its form, gunpowder was extremely dangerous because it was easily accidentally ignited by flame, spark, concussion or friction, even in the hands of welltrained gunners, and, as a precaution, the ammunition number carrying a cartridge to the gun kept it under one arm and covered it with his other hand.

Black powder also always produced clouds of dirty grey smoke, which both obscured the target and exposed the gun position, a distinct disadvantage when fighting the Boers.

Priming and ignition

The gun was primed with a two-inch long copper friction tube. This was ignited by pulling on a lanyard clipped to a piece of roughened metal embedded in detonating composition at the top of the tube where it was held in a copper nib piece soldered to the tube. In the 1890s, the superior 'T' friction tube was produced, but it does not seem to have been taken into use with the 2,5-in RMLs as it is never mentioned in the lists of store for those guns and, in any event, it required a special vent fitting to hold it in place. This vent was only fitted to the steel breech-loading ordnance, such as the 12 and 15 pounder field guns. Despite the general use of the friction tube, mountain batteries were still carrying the old fashioned portfire in the 1890s, in case the tubes failed.

Projectiles

The common and shrapnel shells in use with rifled muzzle-loaders had the same ogival shaped nose which is familiar today, but they had copper gas checks fitted to the bottom. These would expand into the rifling by the explosion of the charge. There were also star shells that contained incendiary charges for signalling purposes or to light up targets at night. These had copper studs around the base, which were aligned with the rifling grooves on loading. Case shot, which was obsolete for field artillery by the 1890s, retained an important role with mountain artillery until well into the twentieth century.

By the mid-1890s, the common shell had been replaced by a new ring shell. This was scored around the body and broke into a far greater number of fragments than did the common shell. The shrapnel shell used with the 2,5-in RML in the 1890s was unusual in that the bursting charge was contained in the head, rather than the base, of the shell, as was the case with that of other artillery.

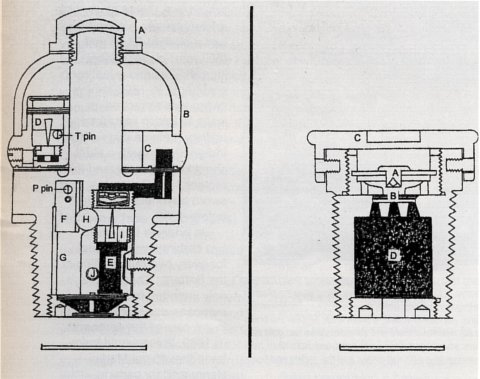

Short Time and Percussion Fuse Mk IV (right) and the Direct Action Percussion Fuse Mk 11/ (far right). Scale: 1 inch. The gun metal Short Time and Percussion Fuse Mk IV (right) had two safety pins, each retaining a detonating needle. Only the first, or T, pin was removed if the shell was to be timed and only the second, or 'P', pin if it was to act on impact. If it was intended that the shell would be timed but also act on impact, both pins were removed. The fuse was timed by first loosening a nut (A) securing a dome (B) which clamped a dual ring (C) in place. The ring contained a power composition train and was turned to the desired position, thus regulating the length of the train, before being clamped in position by the nut and dome. After the shell had been placed in the muzzle, the T pin was withdrawn to leave a detonatig needle in a hammer (D) suspended over a detonating cap by only a thin shearing wire which was broken on the gun being fired, allowing the hammer and needle to set back onto the cap. The resulting explosion of the cap ignited the powder train in the ring and thence the magazine in the fuse (E), which exploded the charge in the shell. If the fuse was only to act on impact, the dial ring was set at a bridge position and the 'P' pin was withdrawn. This left a safety pellet (F) retained by a thin shearing wire which was broken on the gun being fired, allowing the pellet to drop into a cavity (G) thus releasing a ball (H), which had helped to keep a second detonating hammer and needle (I) in place. The centrifugal forces generated by the spinning shell moved both the ball and a retaining bolt (J) away from their positions so freeing the hammer and needle and allowing them to fly forward onto a second detonating cap on impact to ignite the powder magazine in the fuse.

The gun metal Direct Action Percussion Fuse Mk 11/ (far right) did not have a safety pin but its head, which contained a hammer (A) suspended over a detonating cap (B) by a thin brass washer, was covered by a thick brass protecting screw cap (C) which was removed once the shell was placed in the muzzle. On impact or graze, the unprotected hammer was crushed onto the cap which exploded and ignited the fuse's powder magazine (D) and thus the charge in the shell.

Fuses

Efficient fuses properly set were critical to the successful use of the 2,5-in RML. In 1889, four types of fuse were listed for use with the gun, namely the Small Percussion Fuse Mk 1*, the Royal Laboratory 15 Second (Special Priming) Wood Time Fuse, the Short Time and Concussion Fuse Mk 1*, and the Short Time and Percussion Fuse. By 1899, the first three were virtually obsolete and the Mk IV version of the last mentioned fuse was the one in general use. The short burning time of this gun metal fuse restricted the effectiveness of shrapnel air bursts to about 2 500 yards (2 285 m), which would have been all but useless when engaging the Boers.

Apart from the fuses already described, the gun metal Direct Action Percussion Fuse had become available before 1890 and was produced in three marks before 1893. This was a simple but sensitive fuse which would act even if the shell merely grazed the ground. It may have been issued to mountain batteries for use with common and ring shells.

The gun metal fuses were screwed into the nose of the shell and only had the safety pins or caps removed once they had been placed in the gun muzzle.

Ordnance Saddles and Ammunition Boxes

The mules were fitted with ordnance saddles, which changed little during the nineteenth century. The saddles each had a cradle or saddle tree; made from two wooden 'A' frames, which was designed to take the weight off the animal's spine. The form of the cradle top differed slightly according to the load it was intended to carry. Later marks had iron or wooden fittings especially shaped for their particular burdens. The cradle rested on a pair of stuffed leather panels, which had a breast piece and breeching, and was generally secured by two girths and a surcingle. The saddle, including cradle, panels, harness and straps, weighed on average 86 Ibs. Loads were strapped to the cradles and further secured by a strap which passed under the animal. The guns, carriages, axles and elevating gear were carried aligned, head to tail, and the wheels and ammunition boxes were hung on hooks attached to the sides of the cradle frames.

Ordnance saddles with breech and chase portions of the gun.

Leather Punjab pattern ammunition boxes had been introduced in the 1870s and were the type generally used with the 2,5-in RML.

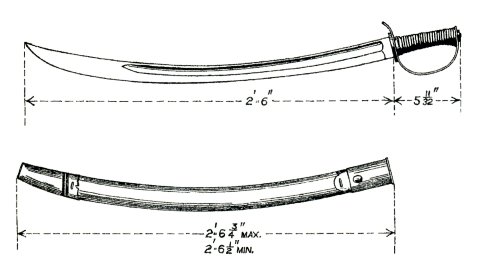

1896 Pattern Mountain Artillery Sword. The sword was always carried

in reverse of the usual practice, with the edge to the rear.

PERSONAL WEAPONS, UNIFORMS AND ACCOUTREMENTS

Personal Weapons

The artilleryman's weapons were his guns and he could ill afford to be encumbered with other arms when in action. Nonetheless, it was obviously necessary for the men to have some form of defence in case their position was overrun.

Officers always carried the 1821 light cavalry officer's pattern sword, which had a steel three bar guard and a steel scabbard. Originally, this sword had a slightly curved blade but, by the 1890s, officers were using a straight blade. From about 1880, the sword was carried in the field in a brown leather covered scabbard with the Sam Browne type belt. Officers also provided themselves with pistols at their own expense. By the late 1890s, the .441 cal Webley revolver, of which there were four marks before 1900, was that approved by the War Office and probably the type possessed by most officers.

Edged weapons of various types were also carried by all other ranks of mountain batteries. The Indian mountain batteries had long carried a sword which had a cast-iron hilt, brass knuckle bow and a heavy curved blade about 30 inches (762 mm) long. However, the men of the Royal Artillery mountain batteries were initially issued with the 1879 artillery pattern bayonet that had a straight 23,75 inch (603 mm) blade, a steel knuckle bow and a leather scabbard. In 1896, a new sword was approved for issue to British mountain artillery, being a copy of the Indian pattern with a steel sheet knuckle bow, and this replaced the Battery's sword bayonets some time before 1899.

In addition to swords, two carbines were issued for every two-gun division in the Battery. These were only intended for guard purposes and were usually in the care of the sergeants. In 1889, these would have been the .45 cal Martini- Henry artillery carbine, which was replaced in the 1890s by the .303 cal Martini-Metford version. The men who were sent to Matabeleland in 1896 (see Part One), were especially equipped with a rifle carried slung over the shoulder. The rifle issued is not identified, but it was probably the .303 cal Lee-Metford as the men certainly carried .303 inch ammunition and the 1888 pattern Mk I sword bayonet for that arm.

Uniforms (see photographs)

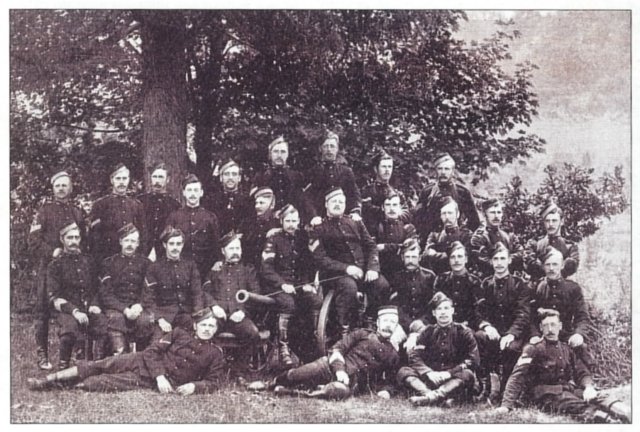

Non-Commissioned Officers of No 4 Mountain Battery, Hay, 1896. The men are all wearing their Undress uniforms as would have been worn in barracks by the men of No 10 Mountain Battery. Most wear the pleated frock, but at least three have the usual artillery frock with patch pockets which they were presumably wearing out. Most frocks had brass grenades on the collar and, not clearly visible, a brass letter 'M' over the brass numeral '4' on each shoulder.strap. As opposed to the warrant officers and sergeants who had gold lace bands on their caps, the corporals and bombardiers wore only yellow braid ones and wore their rank chevrons on the front of the cap. The breeches were dark blue with red stripes and the gaiters and boots appear to be black.

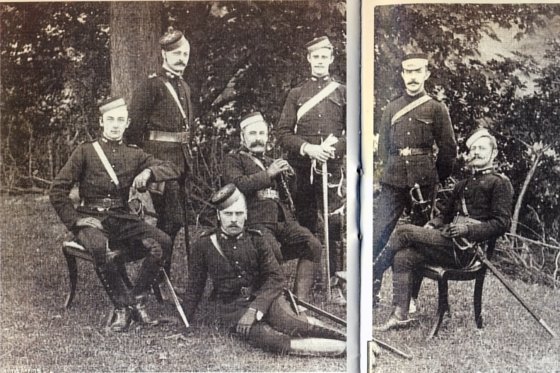

Officers of No 4 Mountain Battery, Hay, 1896. The battery officers are the one on the right and four on the left, the other two being a Royal Artillery adjutant and a Surgeon Lieutenant. The five battery officers are all in the same Undress uniform as would have been worn in barracks by No 10 Mountain Battery. This comprised a dark blue Undress frock with pleats as prescribed for mountain artillery, with gold embroidered grenades on the collars and gilt buttons and rank badges. The cap was dark blue with a gold lace band and gold braid figure and netted button on the crown, and the breeches dark blue with broad scarlet stripes. The Sam Browne belt, gaiters, scabbards, sword knots and gloves were all in brown leather.

Sub-division of No 4 Mountain Battery, Hay, 1896. The men are preparing to fire the gun. From the left, kneeling, No 2 has sponged and rammed home the cartridge and shell, No 4 has served the vent and pricked the cartridge and has a handspike ready to lever back the right wheel after firing. No 5 is holding the friction tube lanyard taut with his left hand and preparing to chop down on it with his right hand to fire the gun and No 1, who would ordinarily have taken post behind the gun to observe the shot, holds aloft the tangent scale which he removed after laying the gun. No 3, standing to the left of No 1, loaded the gun and now has a new cartridge under his left arm, covered by his right hand, and a new shell in his left hand. The sponge water bucket stands beside No 2, a traversing handspike lies outside the right wheel and the trunnion block beside the left wheel. The men are wearing their white buff leather waist belts with a rectangular brass Royal Artillery plate and bayonet frog. The brass insignia on their shoulder straps is more obvious in this photograph.

The other ranks of the mountain batteries were issued with blue trousers with red stripes, and two blue frocks of the branch's own distinctive patterns. One frock, with a red collar and yellow braid ornamentation on the collar and cuffs, was similar to that used by the field and garrison artillery, and was worn on dress occasions, whilst the other, for use at drill, was quite plain and loosely cut, without patch pockets but with two pleats down the front. The usual blue cloth-covered helmet surmounted by a brass ball finial may have been issued to No 4 Mountain Battery, but the other mountain batteries, stationed in the tropics, had a dress cork helmet covered in white cloth with a brass chin chain and the ball finial. There was also a blue pill-box cap for Undress. In 1890, shoulder strap insignia, consisting of the 'M' over the battery number, all in brass, was approved. This was worn with the blue frock, but not the khaki one.

The eleven men who went to Matabeleland in 1896 were issued with a special campaign dress comprising a broad brimmed felt hat, probably with a red puggaree, grey flannel shirts and a dark blue jersey, khaki trousers, and black leather gaiters. When the war began in South Africa in 1899, the Battery's field service dress was the familiar khaki drill, but with dark puttees and a khaki cover over the cork helmet.

Accoutrements

Gunners, being involved in the heavy work of serving their guns, were relieved of the inconvenience of carrying much equipment on their persons and were seldom encumbered with more than a water canteen, a waist belt, a shoulder belt for the sword and, sometimes, a haversack and mess tin. The mules carried everything else. Both the old fashioned wooden 'Oliver' pattern water canteen and the more recent metal circular one were in use by the gunners in 1896 in Matabeleland and were presumably the patterns that had been issued for the entire Battery.

The leather belts and gaiters of mountain batteries in India were ordered to be brown, but photographic evidence indicates that at Pietermaritzburg, the Battery wore Royal Artillery white buff waist belts (as did No 4 Mountain Battery) and blue puttees. In 1896, a white buff shoulder belt was approved for the mountain battery sword and was issued to dismounted men of the Battery with the new sword before 1899. Also in 1896, a special pattern of buff waist belt with a shoulder brace and sword frog was approved for the Battery's mounted other ranks, but although at least one mountain battery in India was issued with this belt, the writer has not seen any evidence of its use in South Africa.

In Matabeleland, the gunners were issued with the mounted infantry pattern brown leather bandolier.

Men of No 10 Mountain Battery who took part in the sortie on the night of 7/8 December 1899. The men are all wearing their field service khaki uniforms with blue puttees and are armed with the 1896 pattern mountain artillery sword. The buff waist and sword belts were not 'blancoed' as they would have been in peace-time. The captured gun is an air-cooled .303 cal 'Extra Light'Maxim Machine Gun, which the Boers were probably not sorry to lose as its air-cooling arrangement did not work well and it tended to overheat very rapidly, becoming dangerous to use after mere minutes in action.

SOURCES

Return to Journal Index OR Society's Home page

South African Military History Society / scribe@samilitaryhistory.org