The South African

The South African

by A V Weinerlein

The Allied navies were hard-pressed to scour the oceans in pursuit of the prowling enemy vessels. The destruction of the Graf Spee at the River Plate was small relief. The early success of the ruthless German Navy inflicted crippling shipping losses on the Allies. With the capitulation of France, the enemy gained many advantageous bases from which to operate their naval vessels. By the end of 1940, over three hundred British ships had been sunk and Britain's accelerated merchant ship building programme had no hope of replenishing the increasing losses due to enemy action.

In the latter part of 1940, Britain placed orders with America to build ships for her merchant navy. At this time, America, perturbed by the adverse shipping losses which Britain was facing, embarked on an emergency replacement ship building programme in order to cover possible losses should they themselves become embroiled in the war.

Keeping up production, workmen lay the keel of another Liberty ship. (Photo: Libertas, January 1943, p 52).

The complete prefabricated transverse bulkhead is lowered into position in the hull of the new ship. (Photo: Libertas, January 1943, p 52).

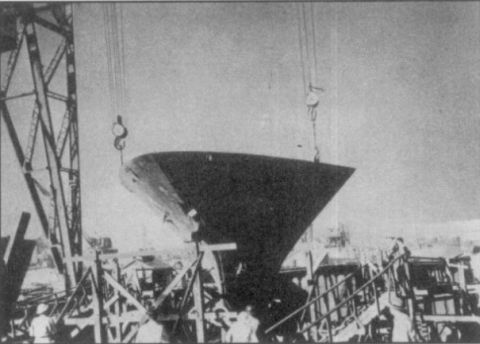

The massive poop deck is manouevred into position. (Photo: Libertas,January 1943, p 53).

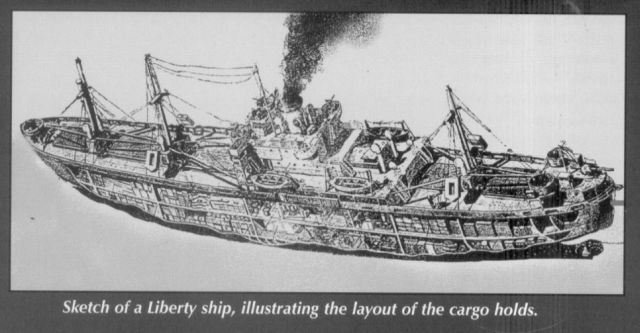

Following discussions between Britain and America on their shipping needs, a standard type of merchant ship which lent itself to mass production was selected. This ship was later to be known as the 'Liberty Ship'. The important features of the new type of ship was that it would be built of steel and welded, having a slightly blunted raked bow with a cruiser stern and a flush deck. The midship decks would accommodate both officers and crew, doing away with the old uncomfortable crew quarters in the fo'c's'le. The engine was to be 2 500 horse power driving a single propeller with a speed of ten knots, carrying a cargo load of 10 000 tons in five cargo holds. The covers of these holds were to be made of steel and wood to be used as rafts in the event that the ship was sunk. The ship would be fitted with suitable armament for defence against both enemy vessels and aircraft.

During 1941, Henry J Kaiser, who had never been associated with ship building, was entrusted with managing the Emergency Ship Building Programme. He was to revolutionise the concept of shipbuilding. It was said that he was 'producing' ships rather than 'building' them.

Huge tracts of coastal and swamp areas were cleared along the Atlantic, Pacific and Gulf coastal areas. The use of swamp areas allowed slipways to be positioned below sea level to aid launching of the ships. For example, the Atlantic area consisted of eight shipyards with 62 slipways.

Some 600 000 men and women from all walks of life were recruited and trained in skills required for mass production of the ships. Towards the end of 1941, the production of Liberty ships got under way and increased at a good rate due to the assembly line method. The keel of the ship would be placed in the slipway, the hull section attached to the keel, and other components such as the engine, the bow, the stern, the boat deck, the engine room and bulkheads, which were fabricated in assembly areas near to the slipway, would be transported to the awaiting hull and manouevred by huge cranes to their allotted positions in the ship. The whole structure would then be welded together. All the deck appurtances were then fitted to the deck, the protective armaments secured at the vulnerable points. The ship, completed, was then launched.

The time spent on assembling a Liberty ship was steadily reduced from thirty-nine days to an average of fifteen days. In one instance, a Liberty ship was assembled in four days, fifteen and a half hours, a once-off effort never to be repeated.

The Liberty ships were prone to certain types of damage owing to the methods used in their production. In particular, the ships had a weakness amidships, where the welded joints did not have sufficient flexibility, and this resulted in cracks across the deck and, in some cases, the ships broke apart. This problem was overcome by placing rivetted plates over the cracks which provided the required flexibility for the movement of the welded hull.

The frugal Liberty ship stood up to intense bombing and U-boat action, adverse weather conditions and heavy seas, acquitting itself well and beyond expectations. The relentless land and sea offensives around the world helped in defeating the enemy on all fronts. The mainspring of victory was the overwhelming sea power of the Allies and the abundance of Liberty ships was a big contribution to this. By the end of the war, 2 710 Liberty ships had been built, of which 200 were sunk by enemy action. Six Liberty ships were sunk off the South African coast by U-boat attacks.

At the end of the war there was a huge surplus of Liberty ships. In the post-war era, they enabled shipping companies around the world to re-establish regular sailings across the oceans.

Return to Journal Index OR Society's Home page

South African Military History Society / scribe@samilitaryhistory.org