The South African

The South African

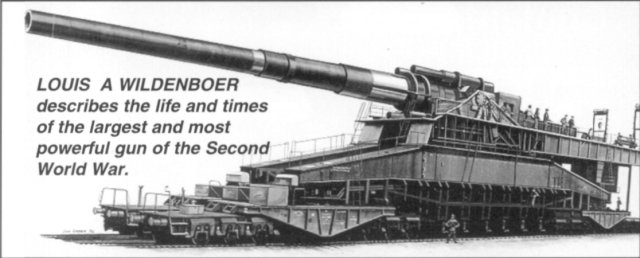

Figure 1: Heavy Gustav, the biggest gun ever built. Note the comparative size of the soldiers. (J Engelmann, German Railroad Guns in Action, Squadron/Signal Books, Texas, USA, 1976).

In the 1930s, the resurgent German arms industry resumed research into the development of guns with long range and fort-smashing ability. In the Second World War, the knowledge gained in the First World War was used to make some notable artillery pieces. There was the 210mm Kanone 12 with a range of 115km, which was used to shell Kent; the famous 280mm Anzio Annie, with a 63km range; and the 800mm Heavy Gustav, the biggest gun ever built. It was not the biggest calibre gun, though. That distinction belongs to the Russian 890mm Tsar Pushka, built in 1586, and now at the Kremlin Museum, Moscow. It was never fired, for fear of the barrel exploding.

For many years, the story of the Heavy Gustav remained shrouded in mystery, as both gun and blueprints were lost during the war. This gave rise to persistent rumours, the most bizarre being that the barrel had been planted upright and disguised as a chimney stack in the hope that it would escape the attention of the occupation forces.

In the 1950s, as Germany returned to normal, the secrets of the gun were slowly revealed as those involved related their experiences. One of the most important contributions came from Dr Ing H Böhm, commander of the Heavy Gustav contingent during the war. In 1959, he published his story. Thereafter, the Nuremberg magazine, Waffen Revue, continued with research into the Heavy Gustav's past. Soon the history of this remarkable weapon was pieced together and put into print. Much of the original data was recovered.

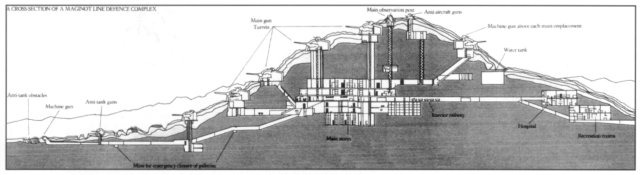

The idea of building this monster gun originated in 1937, when the German Army watched the massive fortifications being constructed on the French border. These became known to history as the Maginot Line, which was based on the 'Impregnable Fortress' doctrine. Its proponent and architect was Andre' Maginot (1877-1932), a First World War veteran and French Minister of War from 1924 to 1931. During that time, he initiated the building of this fortified line. At the same time, the Belgians erected some massive forts on their borders, including the famous Eben Emael, considered totally impregnable.

Figure 2: Section through a Maginot Line Fort (I V Hogg, Forts & Castles,1981).

Incredibly, the lessons of the First World War had not been learnt! The ghosts of Big Bertha and the ruined Liege forts must have appeared again and again before them, but the defence experts carefully looked the other way, and went on pouring more concrete into useless fortifications. The Maginot Line bristled with guns and forts, all built in steel and concrete and designed to withstand any known weapon. Underground was a maze of command posts, living quarters, stores and ammunition dumps. It was the final word in defence, seemingly impervious to any form of attack. André Maginot was hailed a genius, and the line was proudly named after him. It proved to be a questionable honour.

The Germans knew the details of the Maginot forts, and set about devising methods to take them out in case of war. They followed the counter-doctrine to get a gun that could smash the impregnable fortress. Like Newton's Third Law of Motion, where every action has an equal and opposite reaction, history shows that for every weapon a counterweapon is soon developed: For the sword, the pistol; for the tank, the bazooka; and for the fort, the armour-piercing projectile.

In 1937, the German High Command commissioned Krupp Steel to design the biggest gun the world had ever seen. They specified unheard-of requirements: a shell that could penetrate 1 000mm of steel armour-plate, seven metres of reinforced concrete, and 30 metres of compacted earth, at a range of 45km. This range would place the gun outside the reach of retaliatory enemy artillery. Movement by rail was essential, and this implied breakdown into sub-assemblies with final erection on the firing site. Possible targets at this stage included the Maginot Line, the Belgian forts, the coast of England, and Gibraltar. The Russian front was not under consideration at this time.

The Krupp experts went to work, under the leadership of Dr Ing Erich Müller, a physics professor. Krupp eventually designed a gun, the like of which the world had never seen. No doubt the knowledge gained in the 1914 1918 War was put to good use. With due respect to artillerymen, firing a gun is easy. Far more difficult are the design and construction of the gun and the projectile. The real weapon is the shell; the gun merely the delivery vehicle. Making the gun and the projectile requires extensive knowledge of metallurgy, steel-making, explosives, and ballistics, all of which are merely the combined results of applied chemistry, physics, and mathematics. The gun was designed with two concepts in mind: to smash fortresses, and to evaluate long-range projectiles. Research on long-range and rocket-assisted shells was well underway, and this gun would be a useful means of delivery. There is, or course, a trade-off between range and shell size. A longer range can only be achieved with lighter shells or more propellant. The laws of physics decree that you cannot have both. Artillery, for all its glamour, is only applied physics and mathematics. A projectile hurled into the air will obey Newton's laws, and its trajectory can be accurately calculated by taking into account the effects of gravity, air resistance, temperature, wind, and supersonic shock waves. These forces combine to divert the projectile from its initial straight-line course. They will also dictate the propelling force and barrel size for a given projectile and a given range - provided these parameters are within practical possibility.

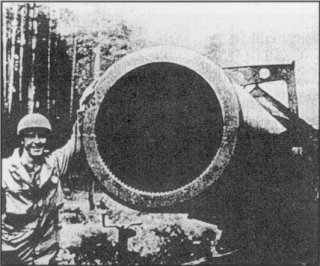

Figure 3: Muzzle of the Heavy Gustav

(J Engelmann, German Railroad Guns in Action,

Squadron/Signal Books, Texas, USA, 1976).

The Heavy Gustav was developed under the strictest possible

secrecy. Even the normal 'Top secret' was considered inadequate.

A special secret order was created. It required that information

exchange should be by courier only. Extreme secrecy and

deliberate misinformation was such that Allied intelligence never

learned of this new weapon. After intensive calculations, Krupp

presented the army with their designs, and in 1939, they were

ordered to construct an 800mm gun in three variants, under the

code name 'Implement D', namely:

Guns D2 and D3 used the 800mm barrel of the Dl as a sleeve for a 520mm barrel insert. The Peenemünde arrow shell and the Rochling rocket-assisted shell were among the projectiles to be tested.

The gun was officially named after Gustav Krupp, director of Krupp Steel from 1909 to 1944, but in many publications the nickname 'Dora' is used. There have been many explanations for this but without any doubt it originated from the secret code name 'Implement D'. Interchanged use of the names 'Gustav' and 'Dora' created the wrong impression that two separate 800mm guns were built.

Construction of Dl started in 1937 at the Krupp armaments factory in Essen. It was not an easy task, since existing workshops had never handled such a monster, and the arms indristry had been closed down for two decades after the 1918 Armistice. Consequently, progress was slow because there were no examples upon which to base the work. So when war broke out, the gun was not ready. Not that this mattered much, for a year later, the Maginot Line had been outflanked with barely a shot being fired at it, and Fort Eben Emael was taken by glider-borne troops who landed on its roof. For a while it seemed as if Gustav might hecome a white elephant, or more correctly, a white mammoth, but the start of the war against the Soviet Union presented new opportunities for Gustav's special capabilities.

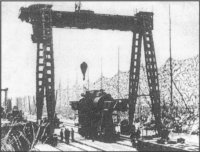

The anatomy of Gustav was staggering by any standards. Nothing like this had ever been seen before (see Tables 1 & 2). Azimuth adjustment was only possible by traversing a curved railway track. Elevation and other functions were electrically powered. Moving this monster took a major effort, requiring a train of 28 special wagons, including two gantry cranes for assembly, and two diesel locomotives for haulage on site. The logistics must have been staggering.

The Heavy Gustav fires at maximum elevation.

(Photo: Bishop and Warner, German Weapons of World War II,

Grange Books, Kent, 2001).

This photograph appears on the contents page of the original Journal.

Equally important was the size of the crew necessary to operate the gun. The actual number of soldiers required was 250, but another 1 250 men were needed to erect, service, overhaul, and protect it. Included was a team of Krupp engineers and scientists whose job it was to evaluate the performance of every shot. At the firing site, railway staff were required to build track and handle the wagons. Four tracks were needed, the outer two for the overhead crane and the inner two for Gustav itself. The unit was commanded by a colonel.

The first gun, Gustav, was completed towards the end of 1940 and the proof rounds were fired early in 1941 at the Rugenwalde Artillery Range. Both Hitler and Albert Speer, his armaments minister, attended the occasion, as well as Dr Porsche of Volkswagen fame. Also on site were twenty physicists and engineers who measured variables concerning the gun and the projectiles for evaluation and research purposes. To eliminate weather influence, infra-red measuring devices were used. From this data, the gun settings and charge for the next round were calculated. The temperature of the powder was carefully controlled, because it affected the rate of combustion, and hence the propelling force.

Test targets for the armour-piercing shell (without warhead) were seven metre-thick reinforced concrete walls and one metre-thick steel armour-plate. Test rounds were fired at short range and on a flat trajectory. The targets were pierced with ease. The steel plate had a clean hole through it as if it had been punched out in a giant press. The high-explosive shell blasted a crater 12 metres wide and 12 metres deep in compacted earth. The test results were highly satisfactory, and exceeded the specifications of the army. Gustav was ready for action, but with no targets lined up.

In early 1941, Gibraltar was considered a potential target, but Spain's dictator, General Franco, was unwilling to allow troop movement through his country, and the plan was dropped. This may have been one of the reasons for the November 1944 decision to cancel the orders for guns D2 and D3, and they were never completed. Only Dl became operational, but after the war, the legend persisted that three separate guns had been built.

The war against Russia suddenly presented new targets for Gustav. The German drive towards the Crimea was threatened by the Russian Naval Base at Sebastopol, which dominated all movement in the Black Sea.

Owing to its strategic significance, Sebastopol was strongly defended by a chain of fortifications over a 40km perimeter, with massive underground bunkers and ammunition dumps protected by heavy artillery and coastal batteries. Many of the forts had famous names such as Fort Molotov, Fort Maxim Gorki, Fort Siberia, and Fort Stalin. Some of the ammunition dumps were more than 30 metres below the seabed, and were considered to be immune from penetration by bombs or shells.

The German Army had to capture Sebastopol, and an attack was prepared. The initial assault was by massive air and artillery bombardment, including that from the 600mm heavy mortar, 'Karl'. This was followed by an infantry infiltration, which failed to dislodge the defenders, who resisted tenaciously from the safety of their underground bunkers. A stalemate developed and eventually Gustav was called in. It was a repetition of the Big Bertha and the Liege forts episode of the First World War, but on a larger scale (See SAAACA Journal July 2000).

In May 1942, the Gustav train left Germany for the firing site at Bakhchisaray, a village outside Sebastopol. The site was carefully chosen to allow optimum use of the gun against selected targets, whilst remaining outside retaliatory range. An eight metre-deep cutting was excavated through a knoll to accommodate the curved railway track, and also to give protection against air and artillery attacks. From the safety of this lair, Gustav would emerge to open fire, and withdraw when finished. Great effort was put into camouflaging the site and a dummy gun position was built a few kilometres away.

To the credit of the security measures, Gustav never came under fire from the air, or from warships of the Soviet Black Sea Fleet, which were well within range. Preparing the site took four weeks, and behind it a small marshalling yard was built to handle the 28 wagons for the gun and its accessories.

Two 110-ton overhead cranes were used to assemble the gun, which, due to the pre-fabrication of most items, took only three days. By early June 1942, Gustav was ready for action. The total number of men involved on the firing site, counting all disciplines such as infantry, anti-aircraft gunners, security police, track layers and artisans, was close to 3 800. It was a massive undertaking.

Bringing the Heavy Gustav into action required superhuman effort.

Here, overhead cranes are used to assemble the enormous gun.

(Photo: J Engelmann, German Railroad Guns in Action,

Squadron/Signal Books, Texas, USA, 1976).

This photograph appears on the contents page of the original Journal.

On 5 June 1942, everything was ready, and like a grandmaster at the chessboard, Gustav proceeded to take out his targets one by one with clinical precision. The type of fortification, and the results observed, determined whether high explosive or armour piercing shells were to be used. Ranges varied from 25km to 42km.

On 1 July 1942, Sebastopol surrendered. With its assignment

completed, there was nothing more for Gustav to do. The gun

was dismantled and returned to Germany for a barrel change. The

worn barrel went to Krupp Steel for relining. The presence of an

extra barrel may have caused the mistaken impression that two

complete guns were built. Afterwards, the Heavy Gustav was

used to fire demonstration and test shots, but never again in

anger. At one stage, the use of the gun was considered in the attack

on Stalingrad or for cross-Channel bombardment of England, but

nothing came of these plans. Thus ended the operational career of

the biggest gun ever built. It fired a total of 300 rounds, of which 48

were in anger. For every shot, the following basic information was

recorded as an input for further research:

After the armistice, the American army found Heavy Gustav intact on its railway lines at the Grafenwöhr Panzer Training Ground. After photographing it, they destroyed it with dynamite. The reason for this act, after the cessation of hostilities, remains incomprehensible.

Possibly, the Americans feared the gun might be used again, although where, when, or by whom remains a mystery. Alternatively, they may have intended to deny the world the knowledge of this extraordinary weapon, or maybe the reason was just wanton destructiveness. Considering the US Army's destruction of the totally harmless Japanese cyclotrons after the war, there may be some merit in the latter explanation.

Whatever the reason, the world was robbed of a unique museum piece - the biggest gun ever built. In contrast, though, Kanone KS, Anzio Annie, was captured intact and transported to the US Army Museum at the Aberdeen Proving Ground, where it is on display.

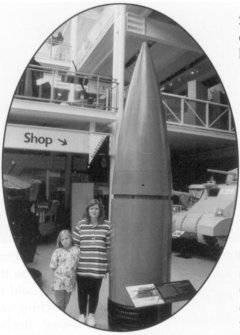

What still remains of the Heavy Gustav are some inert projectiles, including one at the Imperial War Museum in London, where it dwarfs spectators standing next to it. This projectile was acquired from Krupp Steel in 1947, and is one of the few surviving anywhere in the world.

FIGURE 4: A Gustav projectile on display at the Imperial War

Museum, London. (Photo by author courtesy British Imperial War Museum).

The building of the Heavy Gustav has often been described as a massive waste of time and money. In a way it certainly was, although the defenders of Sebastopol may have thought otherwise. On the other hand, had the Maginot Line not been circumvented, and had Gibraltar been available as a target, Heavy Gustav may have played a big role in the German war effort. Many weapons now in common use have at some stage of their development been dismissed as useless. For instance, Napoleon described the submarine as of no use, and the machine gun was described by General Haig as a 'much over-rated weapon'. As it was, Heavy Gustav never really had the chance to prove itself against a target worthy of its immense firepower, and since very little tactical advantage was gained from its war service, the immense expenditure in both manpower and financial terms, could hardly be justified. Nevertheless, Heavy Gustav provided a unique laboratory for the evaluation of heavy projectiles in flight, and the knowledge so gained contributed greatly to further developments in the field of gunnery and ballistics. It was a masterpiece of engineering.

| Table 1 TECHNICAL DETAILS: GUN |

|

|---|---|

| Calibre | 800mm. Four reclining men could fit comfortably inside the muzzle |

| Length of barrel | 32,5 metres, A two-piece barrel in an external sleeve. |

| Depth of rifling | 10 mm |

| Length of firing chamber | 8 metres |

| Breech mechanism | Sliding block |

| Recoil | 3 metres |

| Recoil absorption | Four hydraulic cylinders |

| Propelling charge | Brass obturation case, bagged powder. A device placed behind the charge to prevent gas from escaping to the rear. |

| Mass of barrel (with breech) | 400 tons |

| Life of barrel | Approx. 100 rounds |

| Weight in action | 350 tons. The name 'Heavy Gustav' was thus most appropriate! |

| Length of carriage | 43 metres |

| Elevation | +10deg to +65deg |

| Azimuth control | None |

| Ignition | Electric spark |

| Max Range: High Explosive | 48km |

| Max Range: Armour Piercing | 38km |

| Max altitude reached by shell | 12km |

| Rate of fire | 4 rounds/hour |

| Crew: Artillery division only | 250 men |

| Total Crew: All divisions | 1 500 men |

| Table 2 TECHNICAL DETAILS: PROJECTILE |

|||

|---|---|---|---|

| Muzzle velocity (Max charge) | High Explosive (HE) | Armour Piercing | |

| Projectile | 820m/s (mach 2,5) | 720m/s (mach 2,1) | |

| Time of flight (Max range) | 120 secs | ||

| Penetration: Steel | 1 000 metres | ||

| Penetration: Concrete | 8 metres | ||

| Penetration: Compacted Earth | 32 metres | ||

| Weight | 4,8 tons | 7,1 tons | |

| Length | 3 metres | 2,4 metres | |

| Fuse position | nose | base | |

| Mass of warhead | 700kg | 250kg | |

| Mass of charge | 2000kg | 1850kg | |

| Nose cone | nickel chrome steel | ||

5 June, Target 1: Coastal Batteries

On 5 June 1942 the firing button was pressed and the first round

roared away at 648m1s. The projectile reached a height of 12km

before crashing onto the target after being in the air for approximately

100 seconds. Fall of shot was observed by a spotter plane, which

radioed back the required corrections. After eight armour-piercing

rounds, the coastal batteries were in ruins.

6 June, Targets 2, 3 and 4: Forts Stalin, Molotov and White Cliffs

respectively

After six shots, Target 2, Fort Stalin, was in ruins. Target 3, Fort

Molotov, required seven rounds for demolition. Fort White Cliffs,

Target 4, was known to have an underground ammunition magazine

under Severnaya Bay considered to be invulnerable to conventional

weapons. Since its position was known to German intelligence,

Gustav now zeroed in on the magazine. Eight armour-piecing

projectiles bored down through the sea and through thirty metres of

seabed to seek out the magazine. The ninth shell found the mark and

the fort erupted like a volcano.

7 June, Target 5: Fort South-West Corner

The destruction of this target took seven rounds. On 7 June, firing

was interrupted for four days to service the gun.

11 June, Target 6: Fort Siberia

The destruction of Fort Siberia was accomplished with five shots.

17 June, Target 7: Fort Maxim Gorki

Devastation took five rounds.

Bishop, C & Warner, A, German Weapons of World War II

(Grange Books, Kent, 2001).

Böhm, H, Die 80cm Eisenbahnkanone "Dora" (Wehrtechnischen Monatsheften,1959)

Fritz R K, 80cm Eisenbahngeschütz "Dora" (Article 2000)

Engelmann, J, German Heavy Artillery in World War II (Schiffer

Military History, Atglen USA, 1995).

Englemann, J, German Railroad Guns in Action (Squadron/Signal

Books, Texas, USA,1976).

Hogg, Ian V, History of Artillery (Hamlyn Books, London, 1974).

Hogg, I V, The Guns, 1939-1945 (Macdonald Books, London, 1969).

Hogg, I V, Twentieth-century Artillery (Prospero Books, Ontario, Canada, 2000).

Hogg, I V, German Artillery of World War Two (Greenhill Books, London,1997).

Johnson, Curt, Artillery (Octopus Books, London, 1975).

Pawlas, Karl R, Waffen Revue, March/May 1973, September/November 1974, December/February 1974 (Archiv Für Militär & Waffenwesen, Nuremberg).

Purnell Weapons of War (Phoebus Books, London, 1973).

Orbis War Machine (Qrbis Books, London, 1983).

Return to Journal Index OR Society's Home page

South African Military History Society / scribe@samilitaryhistory.org