The South African

The South African

The intention of this article is to highlight the men and equipment used in the water supply logistical chain on the Western Front during the First World War, with special reference to the men of the 1st South African Brigade.

Introduction

War is a man-made disaster. The opposing forces in the First World War, 1914-1918, tried to destroy the other’s infrastructure, services, and supply lines. Clean water supply is often taken for granted but was of utmost importance to the fighting man in the trenches. Contaminated water, or water drunk from bomb craters, would lead to dysentery, typhoid, or diarrhoea, effectively incapacitating the soldier and adding to the burden faced by the medical services.

Water, the gift of life

All life on earth depends on water. Anyone who has soldiered in the African heat where water is scarce might recall their parched mouth and cracked lips and will know the importance of water. During my military service in northern Namibia, the one Owambo word I learned was that for water, omeya. A soldier’s body weight is about 60% water. Water does more than just quench your thirst and regulate your body's temperature; it also keeps the tissues in your body moist. In wartime, water can also be treacherous. Before the First World War, many soldiers died from water-borne disease and the effects of germs on the body system was not understood. Polluted and dirty water was very harmful to soldiers. It caused many serious health problems such as cholera, typhoid fever, diarrhoea, ulcers, hepatitis, respiratory tract infection and kidney damage. These diseases could be spread while bathing, washing, drinking water, or by eating food exposed to contaminated water. Diarrhoea and vomiting were the most commonly reported symptoms of the fighting man.

Methods of clarifying and sterilizing water

By the beginning of the twentieth century

military medical and hygiene officers recognised

a number of ways of treating water:

Clarifying: Potassium alum, potash alum,

or potassium aluminium sulphate is a chemical

compound that has been used as a flocculent

to remove unwanted colour and turbidity from

water since ancient times. Turbidity is a

measure of the degree to which the water loses

its transparency due to the presence of

suspended particulates and is considered a

good measure of the quality of water.

Potassium alum was commonly used in water

purification in the British Army, after which the

water would be filtered to remove any solid

particles. If the water was cloudy or muddy, the

use of Potash Alum powder, left to stand for an

hour, would clarify the water. A heaped

teaspoon of Potash of Alum mixed with 1/3

teaspoon of Sodium Bicarbonate would treat

100 gallons of water. Later, two tablets of

Sodium Bisulphate into a two pint water bottle.

Chemical sterilization: The use of 2g Calcium hypochlorite per 100 gallons (454 litres) of water was found to sterilize the water.

Boiling: There was a downside to boiling water in open vessels; this method made the water taste flat and bland as the dissolved gases were released. The boiled water had to cool before it could be drunk, it required a large amount of heat to bring it to the boil, and a fuel source was not always at hand.

Heat transfer: The cost in fuel and the length of time required to boil water and then to wait for it to cool enough to drink led to innovations of heat exchange. It was found that if a metallic container with good heat conducting capacity was heated for sufficient time, it would yield nearly all its heat to the liquid which it held. Thus, water boiled to 100°C could transfer its heat to a body of 15°C cold water, causing the cold water’s temperature to rise to 97°C while cooling to17°C. It was also found that it was not necessary to boil water to 100°C to kill all water borne diseases. Water heated to about 72°C for 15 seconds was sufficient to kill these germs. However, water heated to 80°C for just a few seconds was sufficient to kill all diseaseproducing micro-organisms.

The search for a portable water sterilizer suitable for military use

In 1896 the French came up with a sterilizer using the heat exchange principle which the British Army tested but found to be unsuitable. The Americans used an apparatus made by Forbes-Waterhouse in their Philippines Campaign (1899-1902). The British Army also used the Forbes-Waterhouse machines in limited numbers in the Anglo-Boer War (1899-1902). These devices were too large to be portable. The British Army was looking for a water sterilizing apparatus which was light and portable, quick and easy to operate by unschooled soldiers, and capable of supplying a large volume of sterile water which would be rapidly cooled and ready to drink. Some were tested, but were too large, while those that were portable did not supply a sufficient rate of sterile water.

The Griffith Sterilizer

In 1905 Dr DP Griffith submitted a portable heat exchange water sterilization device for testing by the Royal Army Medical College. It was found that by using four of these sterilizers, 250 gallons (1 137 litres) could be delivered during every hour of operation. Individually, each Griffith Sterilizer could easily deliver 60 imperial gallons (273 litres) every hour of operation. The Griffith Sterilizer was easily operated by two reasonably intelligent men from the Royal Army Medical Corps. The heat source was a British, commercial, off-theshelf copy of the Swedish pressure ‘Primus Stove’. The stove had a paraffin capacity of 3½ pints (1,99 litres) when filled to the brim and testing found that if 3 pints (1,77 litres) of paraffin burned for about 1½ hours, it would sterilize 100 imperial gallons (454 litres). The ‘primus’ would burn even in a moderate to stiff wind. After a few months of testing, the Royal Army Medical Corps ‘hygiene section’ recommended that the British War Office accept the Griffith Sterilizer/kettle for field service by the British Army. No List of Changes in British War Material official date of introduction can be found. It is thought to have been introduced into British Army service in about 1909. The responsible personnel for the operation of the sterilizer and, in fact, all water for human and animal consumption was the hygiene officer of the Royal Army Medical Corps. This officer delegated some of the smaller or mundane tasks to men under his command.

The Griffith Sterilizer consisted of two main components: a boiler/heater and a cooler tank. These tanks were of about equal size, approximately 91 cm high, although the cooler tank was a little longer than the heater tank. Both had a water capacity of about 10 gallons (45 litres). The diameter of the heating tank – about 30 cm – was large enough to house the Primus Stove in the lower section. The cooling tank was square, with external measurements of about 30 by 30 cm. The cooler had a separate internal cold water reservoir surrounded by an outer internal container, where heated, sterilised water from the boiler was cooled. The whole apparatus was packed into two wooden boxes and could be carried in the foot box on the standard water cart. The heater/boiler had a mass of 36,3 kg and the cooler a mass of 38 kg. These approximate sizes are confirmed when compared to an image of a standard man of size 1,5 m standing near the set-up apparatus.

In operation, water was first pumped from a water source using the standard issued Mk IV lift and force pump into a standard-issue 400 gallon (1 818 litre) square metal holding tank or water cart Mk II or III. The heater and cooler were placed on level ground about 150 mm apart and connected by two pipes. One pipe transferred cool water from the cooler to the boiler and the other, heated water back to the cooler. The steriliser was connected by a tube from the holding tank or water cart to the inlet of the cooler. The internal reservoir of the cooler, of capacity 10 gallons (45 litres), was filled. Overflow water then filled the 10-gallon water container in the top two-thirds of the boiler. Once the boiler was filled, the primus stove was lit and placed in the lower section of the boiler. A hinged metal door was closed. The whole set up took two men about fifteen minutes.

The metal (thought to be galvanised iron) was heated by the primus stove which, in turn, heated the water in the boiler. When the heated water attained 80°C, a simple thermostat opened and allowed the heated, sterilised water to flow back to the outside reservoir of the cooler. The cold water in the inner reservoir cooled the heated water and, at the same time, was heated. This ensured that the water entering the boiler had already been warmed and less fuel/heat/energy was required to heat the water to 80°C. Only water heated to 80°C could pass to the steriliser reservoir of the cooler via the thermostat. From here, it was piped to a water cart or to another 400-gallon tank which held it for drinking or cooking.

Water was drawn from these containers by small fluted taps into individual water bottles or pots for cooking. In semi-permanent installations the water source of the sterilising process was raised about two metres from the ground and above the Griffiths Steriliser, which was placed above the sterilised water tank or water cart. The outlet taps were usually 30 cm to 90 cm off the ground. This allows for the natural flow of water from high to low.

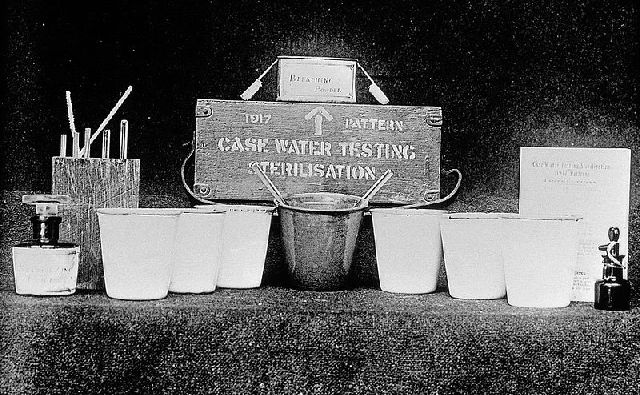

Water Sterilisation Kit

The water source

The Hygiene Officer from the Royal Army Medical Corps was responsible, amongst other duties, for the supply of safe water to the men in the field. He had to decide on the water source to be used. For example, this might be the Somme River in France during the First World War, 1914-1918. Other sources were wells, town pumps connected to underground wells, or piped water from dams. The hygiene officer was responsible for testing and securing the water source. Water not sterilized by filtration, heating or chemical means was not to be used for drinking. The sanitary or hygiene officer also had to ensure that the men were informed not to drink water from any unauthorised sources. Muddy water was clarified before being classified suitable for drinking.

The hygiene officer selected a section of river front away from enemy fire, which was secure from contaminants and flowing quite strongly. To ensure the water was free of microorganisms he used a British water testing kit. Drinking water for the soldiers would be drawn above stream from where horses and mules drew their water for drinking. Bathing or washing would be downstream from both the drinking sources of men and horses.

Equipment used from Source to Storage

Water pumps

The standard pump in use at the start of the First World War, and later with minor modifications, was the Pump, Force and Lift 60 Ft Mk IV or later marks. Each troop within an engineer squadron carried one of these pumps with suction and delivery hoses. These pumps could supply 600 gallons (2 728 litres) per hour when required to lift the water 60 feet (18 metres) from the source. Four men were required to manually pump the water. If the lift requirement was lower, then the delivery rate was higher per hour, even with two men working the pump. Water could be pumped into water carts of capacity 115 gallons (522 litres) or to 400-gallon (1 818-litre) storage tanks. The water carts might also be required to transport the water some distance to a divisional water point with many 400-gallon water tanks. Here the water would be pumped from the water carts into the water storage containers. These storage tanks might be connected to Griffith sterilisers, and the sterilised water piped into water carts for use by the men in the front lines.

Australian men pumping water

from a flooded dugout.

Source: Imperial War Museum

Water carts The type of water carts in service with the British Army in 1914 was the Cart, water tank, Mk II and its slightly modified versions, the Mk II*, the Mk III (introduced into service in 1910), and the Mk IV (brought into service in August 1914). During the war, modifications and improvements were made to all the Marks. These modifications were incorporated into the Mark V and Mark VI, both introduced from August 1915. Further modifications followed and the last were made in July 1918 with the introduction of the Cart, water tank, Mark VI*.

All of these water carts were similar. They had a water tank capacity from 113 gallons to 118 gallons, with suction hoses, the end of which had a bucket-sized filter or strainer. The hand-operated pump had a quadruple action and the capacity of raising 480 gallons (2 180 litres) per hour at 100 double strokes per minute. The pump was mounted permanently to the cart. Some carts had two pumps, one on each side. The Mk III, much like the other marks, had a filtering apparatus which consisted of two separate filters, one attached to each pump. The suction and delivered hoses were of ¾ inch diameter (19 mm). Each filter contained clarifying powder (potassium alum). Stores boxes contained spare parts, tools, grease, and a steriliser with heater. There were minor differences in how and where they were mounted. Included were nine pounds (about 4 kg) of clarifying powder (alum and soda) stored in eighteen 8 oz (225g) tins, and 2¼ pounds (about 1 kg) of bleaching powder (chloride of lime) in nine 4 oz (113g) tins. The carts had a maximum length of between 4,2 m and 5,5 m. The maximum width was between 1,85 m and 1,97 m. The maximum height of the water carts was between 1,47 m and 1,68 m. The mass of the carts, with stores but no water, was between 658 kg and 765 kg. They were normally drawn by two horses or mules.

Water Cart Mk VI

The logistics of daily water supply

Logistics is the term used for the process of getting equipment and supplies to where it was needed at the right time. It entailed detailed planning and coordination. During the First World War, the division was the logistical unit, and the essence of British Army logistics was to supply all the equipment, transport, ammunition, food, and forage needed by a division at any given time. The railways were the main transport used for moving supplies to the divisional supply depots.

Roughly speaking, a division comprised 17 488 men and 585 officers, or three brigades plus divisional troops and artillery. A brigade comprised four battalions, a battalion, four companies, a company, four platoons, and a platoon, four sections. A section was made up of 12 men, no officers. There were about 5 000 horses and mules in a division (1 471 riding horses, 3 350 draught animals, and 127 pack horses and mules). The scale of issue of water carts in 1914 was 60 to a division, 18 to a brigade, and four to a battalion.

Stuck in the mud

The Ninth Scottish Division

The South African Brigade in France formed part of the 9th Scottish Division. This division was formed at the end of August 1914 and underwent training at Bordon in southern England. After completing their training, they sailed for France between Sunday, 9 May and Wednesday, 12 May 1915. Throughout the remainder of the First World War, the Division served on the Western Front in France and Belgium. The South African Brigade, formed in August 1915, also formed up at Bordon and underwent training there. They eventually disembarked at Marseilles on Thursday, 20 April 1916, and joined the 9th Scottish Division between 22 April and 11 May 1916. By this time, there had been many modifications to the written instructions in the Field Service book, drafted in peacetime to assist officers in most situations. After the Battle of the Somme in July 1916, further modifications were made to the logistical system used by the British Army.

On the Western Front (France and Belgium), the 1st South African Brigade, with its four infantry regiments (between 3 000 and 4 000 men) formed one of three infantry brigades of the 9th Scottish Division. This division, at full strength, would have 12 000 infantry, fifteen batteries of artillery, four batteries of trench mortars, three engineer field companies, one signal company, one administration unit, three mobile front line medical units (field ambulances), one veterinary section, one pioneer company and a divisional train unit, a total of about 15 000 men. Full strength divisions were hardly ever the norm, however, and the strength of the division would vary constantly as men were injured, killed or replaced. By 1918, the strength of a division was about 12 000 men. Up to 1917, a British division required 70 fully laden train trucks (700 tons) of equipment and supplies every day. After 1917, with improvements in the British logistics system, each division required 1 000 tons or 100 train loads of material every day. This mass of equipment was mainly moved from the main divisional supply depot on narrow gauge railways to the brigade depots about 3 km behind the line by horse or mule drawn carts or wagons. Thus, by 1917, the British Army employed over 368 000 horses on the Western Front, the vast majority being draught or pack animals. Water was not normally moved by train but sourced locally and moved closer to the front line in water carts drawn by two horses.

The senior officer of the 20th Sanitary Section of the Royal Army Medical Corps was responsible for hygiene and clean water supply. He selected a good water source, usually a flowing river, at least 12 km from the front lines, out of range of German artillery. The water was protected from contamination by other soldiers or animals. Field engineers used hand-powered differential pumps to raise and pump up to 1 200 gallons (5 400 litres) per hour per pump, into large holding tanks.

Daily water requirements

The 1914 British Field Service Pocket Book lays down the daily requirements for men and animals: ‘A daily average of 1 gallon (4,54 litres) is sufficient for drinking and cooking purpose. A horse bullock or mule drinks about 1½ gallons (6,8 litres) at a time. In standing camps, an average allowance of 5 gallons (23 litres) should be given for a man and 10 gallons (45 litres) for a horse.’ At the standing camp rate of water supply, the 9th Scottish Division, at full 1914 strength, would have required 90 365 gallons (411 000 litres) of water for the men, and 49 490 gallons (225 000 litres) for horse and mules, a total of 139 855 gallons (636 000 litres) per day, every day!

Now every soldier knows that the actual scale of issue of equipment and supplies always falls short of what the book recommends. Thus, the men in the 9th Scottish Division could count themselves lucky and grateful if they received a daily water supply of 1 gallon per man per day and 2 gallons per day per horse. A more realistic daily water requirement for a full-strength division would be 18 000 gallons (82 000 litres) for men and 9 900 gallons (45 000 litres) for horse and mules, a total daily amount of 27 900 gallons (127 000 litres). There was usually sufficient water available on the Western Front and it was not too difficult to pump and store the daily water requirement. The difficulty increased, however, when the water moved closer to the front lines ...

Supplying the front lines

Divisional water treatment and storage was, on average, located about 12 km behind the front lines. This was out of range of most of the German artillery. The most numerous German field gun, the 7,7cm Feldkanone 96 neuer Art had a maximum range of 8 400 m with the trail dug into the ground. Later models, with improved ammunition, had a maximum range of 10 700 m. The bigger 10,5 cm Leichte Feldhaubitze 16 only had a maximum range of 9 225 m. The distance from the divisional supply depot to the front lines and back was too far for a water cart team to travel every day over difficult terrain. Brigade supply points were therefore established about 2 to 3 km from the front lines, in range of German artillery, but out of range of German Maxim machine guns. The brigade quartermaster staff was responsible for moving the brigade portion of the 9th Scottish Division supplies from the divisional supply depot to the brigade supply point. As this entailed moving into the range of the German guns, nearly all movement was done at night.

The 1st South African Infantry Brigade had a maximum of eighteen water carts. Each was filled with about 515 litres of water from the then divisional supply point during the day. After nightfall, the water carts moved up to 9 270 litres of water to the brigade filling point, a journey which took about 3 hours. In theory, each man in the brigade would receive about 2,5 litres of water at night. His water bottle would hold 1 075 ml.

Water cart with storage boxes

The brigade quartermaster staff was not able to deliver rations, ammunition, and water to the men in the front lines themselves. The men would have to come and collect the supplies which they needed. No transport or wagons could be used; the men would have to carry everything they required from the brigade supply point to the front line. To do this during the day was nearly impossible and it had to be done by ration parties at night under the cover of darkness.

Only a few men were able to leave the front line and collect their food, ammunition and water. Most had to stay and defend their position against possible attack. Each full-strength company of about 200 men would have a roster, indicating which platoon would be the ration party that night and which platoons would stay behind. Normal night-time duties such as reconnaissance into No Man’s Land, repair to the trenches and barbed wiring parties would continue. Men in the trenches worked at night and rested during the day.

Front line equipment used to transport water

The two-gallon petrol can

In about 1903 the motor car industry started to grow but there were few places available to refuel. Motor cars thus carried a two-gallon (9 litre) steel ‘motor spirit’ can. The shape of these cans allowed them to be packed four to a crate for transport. For many years, they were the main way fuel was supplied. The supplier repaid a deposit on return of the can, but many people lost their deposit as they decided to keep this useful can. There were hundreds of different manufacturers (Albion, Brittol, Caltex, Duckhams, Esso, and Shell, to name a few) and each painted their cans in a bright colour advertising the brand. By the start of the First World War, these cans were quite common. As the war progressed, civilian cans were used by the British Army for a variety of liquids, from petrol, to paraffin to water. They became the main means of moving water from the brigade supply point to the men in the front lines.

Two-gallon can

They had a brass screw cap and a metal handle on top for carrying. When filled, they had a mass of about 10 kg. A soldier could easily carry two of these cans. If carried on a pole, two men could carry six tins. The British Army mostly repainted these cans in an olive drab, but the embossed brand names of some cans remained visible. The Vickers machine gun also used the same cans to circulate water around the water jacket of the barrel to keep it cool. They were officially known as Cans, Condenser, Steam.

Biscuit tins

So-called biscuit tins were also used for transporting water. There were different types and sizes of these tins. The tins for fancy biscuits such as Marie biscuits were cubical tins known as the ‘No 5’ (9. by 8½ by 9½ inches, or 232 x 216 x 241mm). Their maximum water capacity was 12 litres, enough to fill the water bottles of a 12-man section. Biscuit tins, when opened, had their lids removed and it was therefore nearly impossible to carry water in these tins without spilling a large amount. The more common biscuit tins came in two sizes, 30 lb and 50 lb tins. The capacity of these tins is not known but they were thought to be about 18 litres. These tins were often cut open to make other useful items such as funnels to pour water from the two- gallon petrol can into individual water bottles, or the ‘Tin Triangle’ recognition emblem worn on soldier backs to enable identification of own forces by liaison aircraft and artillery observers.

The Flimsy paraffin tins

The Flimsy was an oil, petrol and water can which held four gallons (18 litres). It was made from galvanised steel and was often cut open and the steel used for other purposes.

A Flimsy paraffin tins

Bottle, Water, Enamelled, Mark VI

The Bottle, water, enamelled Mark VI, was approved for British service in 1903 by List of Changes No 11460. The body of the water bottle was in a kidney form and the base of the water bottle was soldered with a ‘tin can’ type seam. The cork was of the normal wine bottle type, was tapered and fitted into the neck of the water bottle firmly. The cork was drilled for an eye bolt, which passed through a galvanised flanged cap. A dished washer and an oval nut held the eyebolt in place. The Mk VI was covered in a thick, three-piece stitched khaki felt cover. The capacity of the Mk VI was 2 pints or 1 075 ml. It was carried in a Web Equipment, Carrier Water Bottle Pattern 1908, on the right hip forming part of the Pattern 1908 Web Equipment. Each man was issued with just one water bottle. This was plainly not enough water for 24 hours and would have had to be filled at least twice a day.

The Ration Party

Every night, all available two-gallon water cans, biscuit tins or flimsies were collected together from each company. Sandbags might be used to carry dry rations and ammunition. If the company had few or no two-gallon cans, then individual water bottles were collected from each man and a section of 12 water bottles was carried in a sandbag. Every night the platoon allocated to be the ration party moved from the front lines back to the communication lines and then through the reserve trenches to collect the ammunition, equipment, food, and water required from the brigade supply point. Hopefully, when the ration party arrived at the supply point, the quartermaster staff would already be there with all the supplies needed. This was not always the case, however, as there might be a delay owing to the difficult terrain or worse, they may have been killed by artillery fire. Water bottles, cans and biscuit tins were filled from the water cart taps at the rear of the cart. Post was also collected. Then, the laden ration party men would make their way back to the front lines. A round trip could take about two hours.

When the Ration Party arrived back the company lines, senior non-commissioned officers (NCOs) would be responsible for handing out the food, ammunition, post and water rations. Water had to be poured from the large neck of the two-gallon can into the narrow neck of each water bottle. For this, a funnel made from either a biscuit tin or flimsy was often used. A two-gallon water container could fill nine water bottles, and a flimsy, 18 water bottles. If there were sufficient containers available, the men could refill their water bottles in the morning as well. This drinking water would have to last all day until the next night, when the water bottles could be filled again.

If water was not sterilised, the hygiene or medical officer with each company or battalion supplied small quantities of chloride of lime to infantry officers who were responsible for mixing up a teaspoon of chlorine of lime into a standard 2 pint (1 075ml) water bottle. The solution was left to stand for a few minutes and then a teaspoon of this solution would be enough to sterilise 9 litres of water for the soldiers to drink. The water bottle with the stock solution was sufficient to sterilise about 430 gallons of water. This was more than enough water for a 50-man platoon for five days. The stock solution would keep for five days in a tightly stopped water bottle.

Conclusion

In the main, the army water logistics system, bringing water pumped at source to the supply points to be collected by ration parties functioned well. There are not many reports of men going without water on the Western Front for long periods. Because this system worked quite well, not much has been written on the topic and hopefully this article will fill the gaps in the known knowledge.

Water bottle place in kit

Source: Karkeeweb Pattern

1908 Associated Equipment

References

The British War Office, Field Service Pocket

Book 1914 (Reprint by David & Charles).

The British War Office, List of Changes in

British War Material, 1895-1918 (His Majesty’s

Stationery Office, London).

Curtin, PD, Death by Migration: Europe’s

Encounter with the Tropical World in the

Nineteenth Century.

Firth, RH, ‘The Griffith Water Steriliser’ in the

Journal of the Royal Army Medical Corps September 1906.

Internet sources accessed 16 September 2019:

Return to Journal Index OR Society's

Home page

National Army Museum, ‘Horse power in the

First World War’, www.nam.ac.uk

Great War Forum, ‘British Biscuit Tins’,

www.greatwarforum.org/topic

Motor Sport Magazine Archive, ‘Petrol Cans’,

www.motorsportmagazine.com,

https://twogalloncan. co.uk